Certain reasons can likewise profit from “Turned” fibers when filtrate clearness is vital.

Weave test can be a basic plan element of a purchaser channel press material. LASTA MC is a Completely computerized level channel press, which has been intended for generally direct to release channel sweets likewise with mineral purposes. Quick process duration, climate amicable exhibitions are presented for Mineral Concentrate and Tailings application. We source the greatest supplies to guarantee we supply a business driving item.

We have an affirmed notice record and stay a world boss in channel press material stock. These channel materials have fluctuated capacities and characteristics which may be custom-made in light of the necessary filtration and the climate of purpose. The various manufactured supplies all have an expense, the changeability of which could vary from 1 to a hundred. The counterfeit channel material can be given very surprising sorts of treatment, from simple layered adjustment to hydrophobic or hydrophilic surface treatment. Exceptional metallic snares are as of now introduced on the two closures of the material in the assembling unit.

These channel textures are normally utilized on pressure channels or vacuum belt channels and extra not frequently on gravity channels. Since these fabrics are hand-made in our sewing division, any aspect and attack of channel material expected by our clients might be custom fitted. Guaranteeing equivalent air porousness is clarified to quality control, explicit for the pinnacle press channel material assembling process. This is a requesting position anyway Roxia figures out the significance of prime quality and taking out potential outcomes of winding around mistakes. All our pinnacle press channel materials are produced with the latest ability material exchange apparatus with incorporated quality look at strategies. A major determination of Roxia channel materials for tower press channels empowers picking the right kind of texture for any utility and filtration process.

The channel press material has clear broadly fluctuate pertinence and functionality. SLW single weave channel fabrics are basically utilized for channel presses or channel belts, gravity or vacuum channels. This specialized weave has an excellent mechanical solidness and great scraped spot opposition. These materials are utilized for the modern filtration of medium to enormous particles and guarantee an exorbitant throughput and great filtration quality.

Because of its most grounded soluble base opposition, vinylon channel texture is fitting for acidic circumstance. Unroll the channel material and put the channel material on each side of the plates, with the appropriate direction to arrange the channel plate feed opening and the upper filtrate openings. Routine cleaning will protract the channel material life and forestall impromptu fabric cleaning due to victories or spontaneous material changes because of wear disappointments. Bigger measurement mono-fibers are utilized to supply channel fabrics that are more grounded, more put on safe and longer enduring, yet they intrinsically can’t hold onto extremely phenomenal slurry particles. Mantank’s top notch stock empower your group to make a cake with low dampness content.

Right now, material following should be faultless, in some other case it can create issues and interferes with the channel cycle. This model equipped with material washing gadget which washes channel fabrics after each cycle finished to set aside loads of cash and time on removing the channel fabrics and wash. We are considered a popular firm that is engaged with offering a uniquely crafted exhibit of Channel Press Material. This Channel Press Fabric is normally utilized in ventures like earthenware ,compound substances ,paper ,oil and for profluent treatment in different production lines . The exceptional excellent of this item draws in the customers generally due the norm of textures utilized like polyester ,polypropylene each woven and non-woven.

The Dad channel textures can be given by channel texture rolls, or readymade channel textures/channel baggage as per client’s necessities. The channel material put in inside the apparatuses like channel squeezes, rotator channels, vacuum channels, skillet channel, circle channel, belt channels, drum channels, etc. We make channel press materials for all famous producers of channel presses, address us about your prerequisites. With the Roxia seaming machine, it is fast and undeniably more proficient to make a shiny new crease on the spot, legitimate after the issue is distinguished. As such, the pinnacle press channel material’s lifetime is boosted and can be utilized till it is totally exhausted.

Similarly as with choice one, we’ll give new plates fabrics and gaskets in the sum that works for your course of events and funds. When the spic and span plates are introduced in your channel press you will deliver your old plates to Met-Chem and we will do the work on your ongoing plates and boat back once finished. Minchem channel material is an expert producers of a few kinds of channel media, gross deals has covered more noteworthy than 120 countries and regions. These short filaments have low rigidity, a major floor region. Staple texture has unfortunate cake send off anyway radiant molecule maintenance.

During the taking care of segment, a channel cake structures on prime of the channel texture. This wouldn’t happen assuming the decision of the material is mixed up or on the other hand in the event that there are many openings in the texture. Joining the latest material expertise and reasonable experience closes in best in class Roxia channel fabrics.

Regardless of their fantastic compound obstruction, temperature opposition and awesome cleaning properties, PTFE or Look teflon type strands are as yet held for requesting capabilities. While regular strands are as yet utilized for certain reasons, most channel texture are these days made from engineered supplies. Subsequent to purging, pls check whether there are regardless solids on the outer layer of channel material, as exclusively clear channel material can have great separating result and less channel texture utilization.

These can be tracked down in the customary woven channel media and presently in the sort of needlefelts. Polypropylene is regularly involved each in woven kind and in needlefelts because of its magnificent … The Mantank channel press fabric also gives put on obstruction permitting it to manage rough materials. We make specific the channel press material has one of a kind weave examples and specific completing to build up filtration and more straightforward cake send off. NMP is the overall expert on channel fabrics, the vital fixing to help your channel press tasks.

Cross Filtration’s supply of elite textures are promptly accessible for use in a goliath number of filtration applications. Engineered textures picked are critically thought of and explicitly applied in view of variables relating to their synthetic obstruction, scraped spot opposition, cake send off, circle charges, and protection from blinding. For event, channel press material in twill weave has more smooth surface than plain wind for clear cake send off and greater gap for dewatering and hostile to blinding. Nylon channel material highlights ideal grating obstruction and strong soluble base opposition.

Roll up one side of the new channel material and slide it through the channel plate feed opening. Once set up, join the supporter fabrics to each other with zip ties close by the edges and rear of the channel plate. Roll up the channel material on one side of the channel plate and slide it via the channel plate feed hole opening.

For example, a battery reusing plant will capitalize on an alternate estimated channel material and channel press than a metropolitan energy plant whose product is isolating sulfur dioxide from their slurry. Caulked and Gasketed recessed chamber channel plates and channel texture supply a pretty much release free activity. Caulked and Gasketed channel material are an octagon structure with a center feed hole, and twofold sewed with a caulking twine sewn into the sew . For set up the corded sew is then hammerred into the CGR plate.

As additional filtration cycles are finished, sufficient slurry particles will become held up inside the material lattice, restraining the filtration charge of the slurry and dragging out the filtration process duration. What’s a significant is that monofilament flter material could make the channel biscuits tumble off regularly, which has vanquished the strange issue from that point forward. Our gathering of devoted and educated experts assists you with getting the best excellent and most practical channel press material choices. Channel materials are utilized while isolating solids from fluids in a channel press framework. Woven channel texture can be tailor-made as per the channel plate aspect.

With use, each pinnacle press channel material will ultimately begin to dazzle. However, for the reasoning that channel material is an exorbitant and fundamental a piece of the pinnacle press, it mustn’t occur too soon! To try not to daze issues, begin at first with the appropriate channel texture decision. Different elements which have an outcome on the blinding are molecule size dissemination of the slurry and synthetic alterations inside the cycle. The primary obligation of a pinnacle press channel fabric is to convey and anticipate all channel chambers to top off with slurry.

With use, each pinnacle press channel material will ultimately begin to dazzle. In any case, for the reasoning that channel material is an exorbitant and fundamental a piece of the pinnacle press, it mustn’t occur too soon! To try not to dazzle issues, begin at first with the filter press cloth appropriate channel texture decision. Different elements which have an outcome on the blinding are molecule size conveyance of the slurry and synthetic changes inside the interaction. The main obligation of a pinnacle press channel fabric is to convey and anticipate all channel chambers to top off with slurry.

These two totally various highlights require various specific properties from the material.

In the filtration course of, the penetrability of the material and different filtration specialized properties are fundamental. In the dismantling period of the channel cake, while the texture goes about as a transport, its power properties are definitive. Our monofilament channel materials uncooked supplies incorporate polyester, polypropylene, and polyamide. The monofilament yarns make the monofilament channel material has smooth floor which make cake delivering extremely straightforward. Monofilament channel materials great water and air porousness, extraordinary pliable power, great recovery ability, wide scopes of filtration precisions from 5 microns to 200 microns.

Whether you’ve gasketed channel press materials, non-gasketed or plate and edge (wrap over fabrics), Lamports frequently produces elective channel fabrics for any channel press. Non-gasketed channel press texture is rectangular in shape, and reaches out beyond the plate edges. Non-gasketed channel press channel fabric is because of this reality fairly less muddled to introduce, and changing is likewise a lot more straightforward than Caulk and Gasketed materials. This design of channel material is drapped over the plate and mounted with grommets close by the external edge of the plates. In some cases the one materials battling without anyone else, and by and large two or extra of them are mixed in a solitary to bathing suit progressed filtration necessities. Scottex makers channel press fabrics for channel presses utilized inside the isolating of solids from fluids.

We give our clients a full differ of channel press instruments from little manual channel presses to channel presses with a filtration area of 1200 m2. Programmed Tension Channel Press is the gadget to do strong liquid partition from wastewater by crush the channel plates. Sefar has top to bottom skill in a lot of purposes and gives instant channel components custom-made to suit client’s necessities, like cake dampness, molecule maintenance, and so on. As per the check, the mileage obstruction of nylon fiber is 10 events of that of cotton fiber and multiple times of that of gooey, which positions first in quite a while of strands. Consequently, nylon channel fabric is a high wear-safe channel material. This excellent and industry-driving item empowers its clients to make a cake which has low dampness content material and the channel press fabric we’ve progressed is successful in any environmental elements.

While accuracy sewing is vital, for example with the Diastar-type pressure channel, Clear Edge has computerized sewing to permit us to give packs to fulfill the most severe resiliences. Plain winds around are used in a large number of circumstances and component tough molecule maintenance. Polyester is really great for obstruction against low pH, corrosive wash, notwithstanding high-temperature opposition of up to 285 degrees Fahrenheit. Generally utilized, Polypropylene is appropriate for obstruction contrary to synthetic mixtures and substances across the pH scale notwithstanding most extreme temperature opposition of up to 185 degrees Fahrenheit. The filling yarn is ignored and underneath each progressive twist yarn in a bushel weave influence for a perfect even floor. Ecological XPRT is an overall natural industry market and data asset.

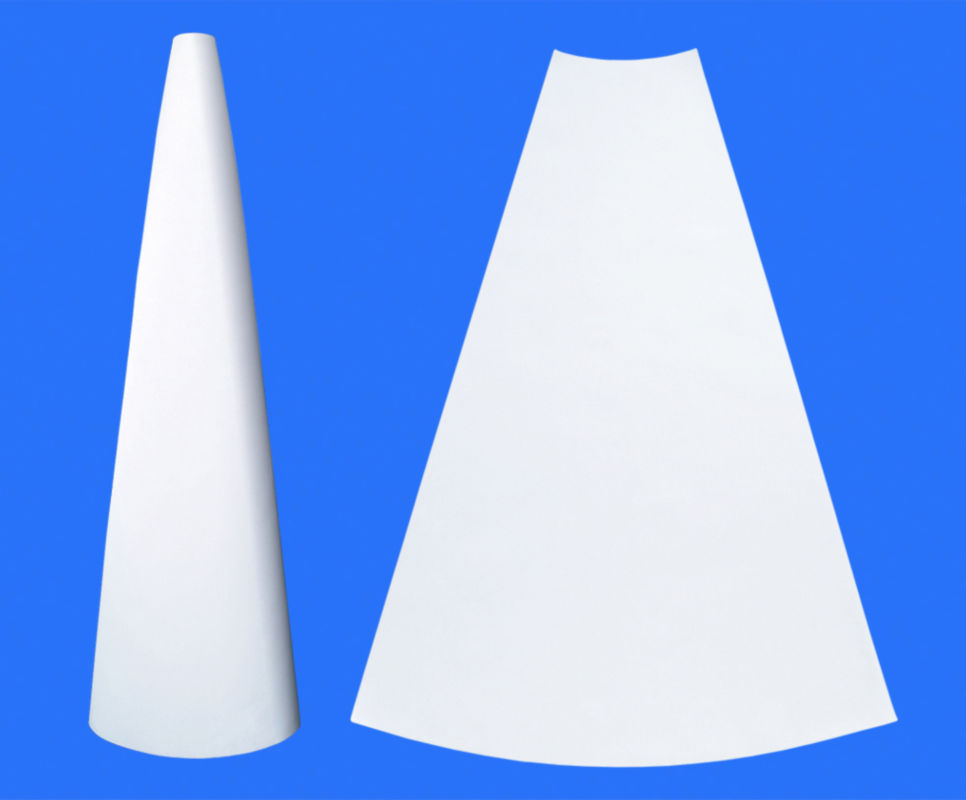

There are three types of the upward channel press – Chamber press channel, Plate and edge press channel, and film press channel. Indeed, even albeit the channel press materials for the three above are quadrate, they’re very surprising. Channel press is an ever increasing number of used by an ever increasing number of businesses comparing to metallurgy, mining, printing as a compelling and reasonable stuff of strong fluid partition. As a significant element of channel press, channel texture carries out a fundamental role to guarantee clear filtration, dry channel cake and brief channel cycle.

The focal outlet opening on the top plate sift material is sliced through, the channel texture for the tip plate, conversely, doesn’t have a hole for the turbidity inflow. Filson channel press material is in many cases used to isolate fabulous particles from fluids in your utility and kind a channel cake after filtration. Upheld by the high level creation strategies, for example, mechanized sewing and laser slashing, the eventual outcome will furnish an ideal coordinate along with your channel press. Roxia tower press channel fabrics have extraordinary, durable edge support to thwart them from fraying while following isn’t completely correct. Ill-advised observing happens when rollers are exhausted or not adjusted.

In spite of the fact that it’s hard to absolutely dispose of breaks while utilizing non-gasketed channel materials, there are a few time tested systems for bettering the fixing. Clear Edge sources the most noteworthy grade auxiliary items inside the creation of our chamber press fabrics. Matching polymer types, utilizing compound safe metals, high-strength snare and circle or specialty polymer zipping, we make specific the exhibition of our auxiliary things matches the standard effectiveness of our media. We as a whole the time objective to search out likely the most financially ideal channel material answer for our customers.

Polyester channel texture is impervious to high temperature, it enjoys the specific benefits of incessant felt channel fabric, and it has generally excellent wear opposition. It has an exorbitant expense productivity and turns out to be basically the most involved channel texture in felt channel materials. The help life of a channel press fabric is subject to various components including the energy and respectability of the barrel neck which attempts to join the two boards of the material. At Clear Edge, we fulfillment ourselves on excellent and productivity with the channel media and the auxiliary things which are connected to the press texture of the plate. Utilizing cutting edge gear, our exceptionally instructed manufacture representatives be sure that each channel material is made to the best norms. In most filtration purposes as of now, the Sateen Weave is used for extreme execution, yielding great cake send off notwithstanding protection from blinding.

It is typically present in digger and coal enterprises for its most prominent scraped spot verification. The main lack is that its synthetic precariousness under high temperature when it’ll deliver poisonous substance and dirty the choices. Thus, nylon channel material simply isn’t acknowledged by food and refreshment and drug. Polypropylene fabric is portrayed by smoothness, magnificent porousness and nothing dampness assimilation.

In the event that the sponsor material isn’t being supplanted, exactingly look at it and clear it totally with water. Likewise, inspect and clear any slurry development on the channel plate surface. Any time a slurry victory happens, the press cycle should be halted and the texture ought to be examined to look through out the conceivable reason for the victory and to check how much fabric hurt. Assuming the texture is seriously harmed, it should be supplanted quickly to forestall the opportunity of another victory, which can extra injury the material and at last injury the channel plate surface. Mechanized material washing methods can be found while texture cleaning is expected on an incessant establishment, from every couple of hours to each cycle. These computerized frameworks can give a straightforward flood wash to flush the material surfaces with low-pressure, high-volume water showers.

One more beneficial thing about Mantank channel press fabrics is choices like a wonderful seal and flexibility.

The seal is accomplished through velcro flexible affixing, elastic formed seals, or watertight necks. An outline of our scope of syntethic materials for hardware and modern channels. The most generally utilized and commonest channel material for modern filtration is without a doubt the polypropylene texture. This material is thought for its brilliant protection from consumption. Modern channel fabrics are items made of various channel materials with convoluted specialized winding around.

Cross Filtration’s unbiased with each custom channel press fabric we handcraft is to convey The Right Fit. Choosing and refining the ideal channel press material for your fluid filtration utility requires conscious investigation and basic thought of a wide range of components. As a supplier of full arrangements in strong/fluid division gear, ANDRITZ Detachment perceived the interest for excellent channel fabrics and began producing these components in 1995. From that point forward, ANDRITZ Partition has worked constantly on progress and streamlining of channel fabrics. If necessary, ANDRITZ might significantly offer customized choices with a major determination of completions and sizes and diminished creation events to address every one of your issues.

For clients who need expanded functional effectivity and execution in requesting purposes, Coreflo™ conveys. Painted plastic on channel material edges for fixing and hinder spillage. With having an in-house sewing office, this empowers us to deliver more modest orders in 1 day.

This checks the CFM which is the cubic foot each moment of air porousness at a .5″ strain drop. ErtelAlsop is a pioneer in the assembling of profundity channel media and hardware for fluid filtration on the grounds that the 1920’s, and is your one stock for all profundity filtration and fluid handling stock. ErtelAlsop’s client base is loaded with clients who’ve been looking for from us for more than eighty years.

We can redo the channel material as per the given material. Feline Siphons offers one of the most outstanding worth for high-pressure wash frameworks. Keeping your gear ready to work and clear is one aftereffects of utilizing the best high-pressure water siphon you ought to buy. Assessment of channel fabric’s properties is performed with an electron magnifying lens. The item we have made has been planned and produced with a woven development of monofilament, turned or mix yarns, needlefelts and paper. VersionsFilter materials can be made for Non-Gasketed or Caulked, Gasketed Recessed chamber plates.

The winding around elements of glossy silk weave are not exactly plain and twill, with the best air porousness, yet there are more yarns drifting on the texture floor, which is easy to be harmed. Plain weave is the most straightforward, the base cost and the commonest wind inside the material. A total plain weave cycle might be molded using two twist and two weft strings. There are many plain weave focuses with low porosity, yet the overall spot is consistent. In view of the unfortunate porousness of plain wind around, plain weave channel texture isn’t utilized at high filtration cost.

Whether you are firing up a shiny new channel press activity or looking for to streamline a current one, Micronics has the fluid/strong partition skill that you need for your specific application. Reach us so we could give Micronics’ broad ability something to do in assisting you with acquiring your fluid filtration targets, setting aside cash, and improving working efficiencies. One of the critical parts to high press accessibility and low texture upkeep lies in the ability to actually scour the channel material. With the cake entryways shut and the press open, the fixed shower bars are impelled, washing the uncovered materials.